- Sourcify

- Posts

- From The Shed to L’Oréal: Medik8’s Methodical Rise in Skincare

From The Shed to L’Oréal: Medik8’s Methodical Rise in Skincare

Nathan and Aaron dissect Medik8’s unique “CSA” framework (Vitamin C in the morning, Sunscreen by day, Vitamin A at night), explaining how clear, habit-forming routines became a cornerstone for consumer loyalty and retention.

The episode unpacks Medik8’s growth strategy, including their unconventional start through professional channels like medispas and dermatologists, the transition to retail and D2C, and their eventual partnership with private equity for rapid expansion into the US.

3 Lessons from Medik8’s Playbook

🔹 Professional Channels Build the Base

Before D2C or retail, Medik8 leaned on dermatologists, medispas, and estheticians. That credibility-first approach created loyalty and retention that made later channel expansion smoother and stronger.

🔹 Simple Frameworks Stick

The “CSA” routine—Vitamin C, Sunscreen, Vitamin A—turned complex science into a daily habit. In beauty, supplements, or beyond, the brands that win are the ones that make consistency simple.

🔹 Operational Capital Beats Fast Money

Rather than chasing quick VC dollars, Medik8 partnered with private equity that brought operational depth and global reach. The payoff? Scaled revenue, expanded distribution, and a more valuable exit—proof that the right partner accelerates growth without losing founder focus.

Leave us a review and let us know what you think of this episode on LinkedIn or Twitter.

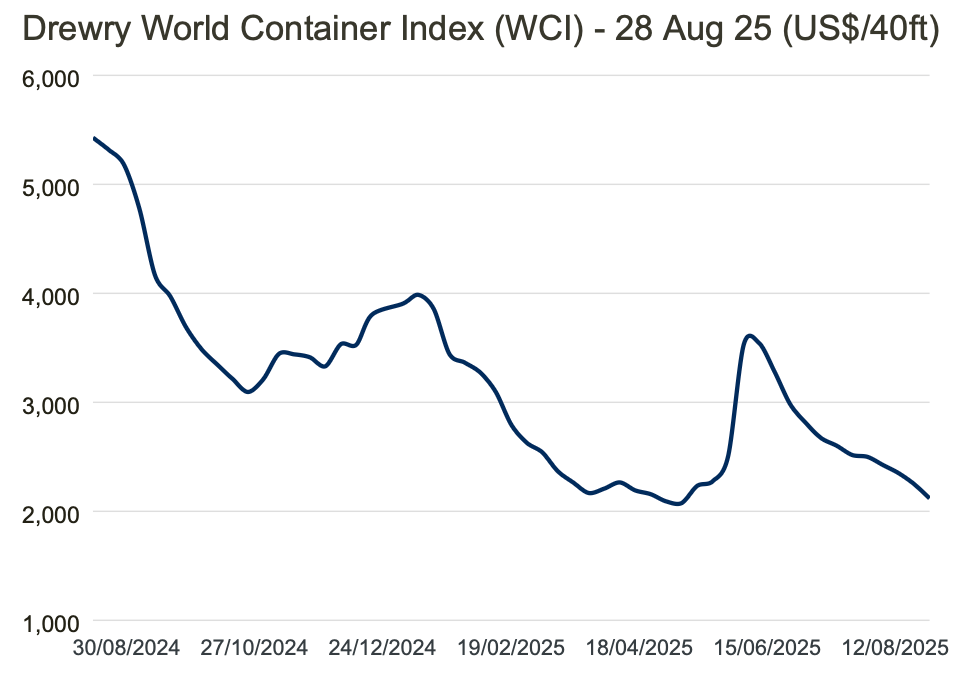

International Container Shipping Rates

Container rates are sliding after an early, tariff-fueled peak season, and with capacity outpacing demand, we expect further declines across transpacific and Asia–Europe lanes.

For brands, the signal is clear: don’t mistake today’s lower freight for stability — plan sourcing and fulfillment with volatility in mind.

Like What You See?

📘 New Ebook: Could You Move Next Month If You Had To?

Supply chains don’t break on your schedule—they break on theirs. A sudden tariff shift, a quality issue, or a factory closure can force a move overnight. The question isn’t if it could happen, it’s when.

That’s why we built this guide. Inside, you’ll learn:

The warning signs your current factory isn’t sustainable

How to prep backup options without doubling your workload

What it really takes to shift production in 30 days or less

Because the best sourcing strategy isn’t the cheapest—it’s the one that keeps you moving when the unexpected hits.